Understanding the Art of Welding: Exactly How to Stay Clear Of Undercut Welding Issues for Flawless Fabrication Outcomes

By comprehending the root triggers of undercut welding and implementing reliable techniques to avoid it, welders can raise their craft to brand-new degrees of quality. In the pursuit of flawless manufacture results, grasping the art of welding to prevent undercut issues is not just an ability however a requirement for those aiming for excellence in their job.

Recognizing Undercut Welding

To stop undercut welding, welders need to ensure proper welding parameters, such as adjusting the current, voltage, travel speed, and maintaining the correct electrode angle. By understanding the causes of undercut welding and implementing preventive steps, welders can achieve top quality, structurally sound welds.

Causes of Undercut in Welding

Understanding the aspects that contribute to undercut in welding is crucial for welders to create high-grade, structurally sound welds. Insufficient welding current or inaccurate welding speed can likewise add to undercut. Comprehending these reasons and implementing appropriate welding methods can aid prevent undercutting concerns, ensuring sturdy and solid welds.

Techniques to Avoid Undercutting

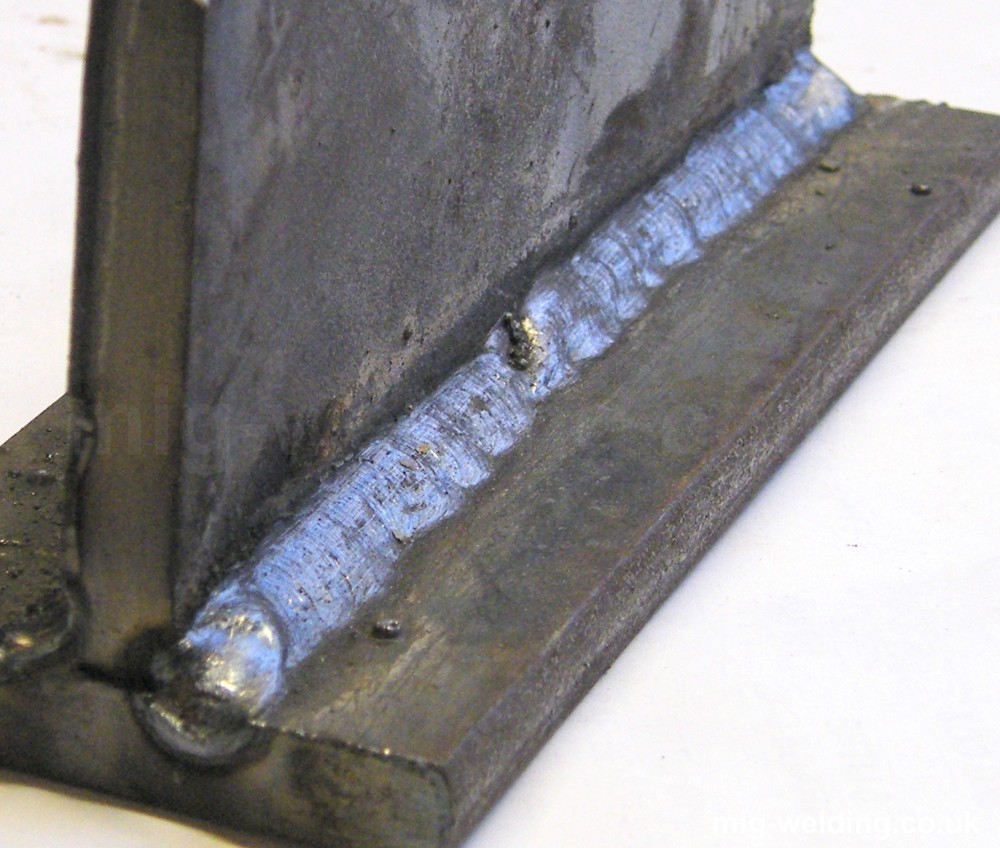

To reduce the danger of undercutting in welding, welders can employ tactical welding strategies intended at enhancing the high quality and stability of the weld joints. Furthermore, making use of the correct welding method for the certain joint setup, such as weave or stringer beads, can contribute to lowering damaging.

Utilizing back-step welding strategies and managing the weld grain profile can likewise aid distribute warm evenly and reduce the threat of undercut. Regular assessment of the weld joint during and after welding, as well as executing top quality assurance steps, can assist in spotting and attending to damaging concerns without delay.

Importance of Appropriate Welding Criteria

Selecting and preserving appropriate welding criteria is important for accomplishing effective welds with minimal problems. Welding specifications describe variables such as voltage, existing, take a trip rate, electrode angle, and shielding gas flow rate that directly affect the welding procedure. These criteria have to be thoroughly changed based on the sort of product being bonded, its density, and the welding method used.

Correct welding criteria make certain the right amount of warm is related to thaw the base steels and filler product consistently. If the specifications are established as well high, it can cause extreme warm his comment is here input, triggering spatter, burn-through, or distortion. On the various other hand, if the criteria are also reduced, incomplete combination, lack of penetration, or damaging might happen.

Quality Control in Welding Operations

Conclusion

Finally, understanding the art of official site welding needs a detailed understanding of undercut welding, its reasons, and techniques to prevent it. By ensuring correct welding specifications and implementing top quality assurance techniques, remarkable fabrication outcomes can be accomplished. It is important for welders to consistently make every effort for excellence in their welding procedures to prevent undercut issues and create top quality welds.

Undercut welding, a common flaw in welding processes, takes place when the weld metal does not appropriately fill up the groove and leaves a groove or anxiety along the bonded joint.To prevent undercut welding, welders need to guarantee correct welding parameters, such as readjusting the current, voltage, travel rate, and maintaining the right electrode angle. Inadequate welding present or i thought about this incorrect welding speed can likewise add to undercut.To reduce the threat of undercutting in welding, welders can utilize critical welding techniques aimed at improving the top quality and integrity of the weld joints.In verdict, mastering the art of welding needs a thorough understanding of undercut welding, its causes, and methods to stop it.